AVDS-1790 Engines

Equipment Intelligence

The AVDS-1790-2 Series Diesel Engines are Military-Grade V12 Air-Cooled Main Propulsion Units. There 1790 cubic-inch displacement engines provide output shaft torque between 750HP and 1500HP. Military Vehicles which use these engines include the M60 Tank, M48 Tank, M88 Tank Recovery Vehicle, the AVLB Bridge Launching Vehicle and the Merkava Tank.

More than 35,000 AVDS-1790 engines has been built since its introduction in 1962 by Teledyne. L3 acquired the AVDS-1790 range from Teledyne as L3 Propulsion Systems. Lately, Renk America Combat Propulsion Systems have acquired the rights to the AVDS-1790 Engine Range.

As of 2022, three models of AVDS-1790 are most predominantly in use:

- AVDS-1790-2CA - Used on M60 Tanks

- AVDS-1790-2DR - Used on M88A1 Tank Recovery Vehicles and AVLB

- AVDS-1790-8CR - Used on M88A2 (Hercules) Tank Recovery Vehicles

AVDS-1790 Biography

AVDS-1790 Biography

AVDS-1790 Original Series

AVDS-1790 Product Improved Series (RISE)

AVDS-1790 High Horsepower Series

AVDS-1790 Technical Manuals

AVDS-1790 Technical Manuals

- MIL-DTL-62177E

- DETAIL SPECIFICATION

- NMWR-9-2815-220

- NATIONAL MAINTENANCE WORK REQUIREMENT

- TM-9-2815-200-35

- MAINTENANCE MANUAL AVDS-1790-2M AVDS-1790-2A and AVDS-1790-2AM

- TM-9-2815-220-24

- MAINTENANCE MANUAL AVDS-1790-2CA AVDS-1790-2DA and AVDS-1790-2DR

- TM-9-2815-220-24P

- PARTS MANUAL AVDS-1790-2CA AVDS-1790-2DA and AVDS-1790-2DR

- TM-9-2815-220-34

- MAINTENANCE MANUAL AVDS-1790-2C and AVDS-1790-2D

- TM-9-2815-220-34P

- PARTS MANUAL AVDS-1790-2C and AVDS-1790-2D

- TM-9-2990-205-34&P

- PARTS & MAINTENANCE 5HDR TURBOCHARGER

- TM-9-2990-206-34&P

- PARTS & MAINTENANCE T18C01 TURBOCHARGER

AVDS-1790 Technical Bulletins

AVDS-1790 Technical Bulletins

- TB-9-2300-403-45

- CONTINENTAL AV-1790 REPAIR OF ALUMINUM OIL COOLERS

AVDS-1790 Maintenance Work Orders

AVDS-1790 Maintenance Work Orders

AVDS-1790-2 Features

AVDS-1790-2 Features

M60 Tank Powerpack Configuration

M60 Tank Powerpack Configuration

Teledyne Continental Motors General Products Division developed the M60 Tank Powerpack as a ready-to-install system. Each individual power pack was "mated" and performance tested at the factory prior to shipment. The power pack for the M60 Series Main Battle Tank consisted of an AVDS-1790-2C (RISE) engine "mated" to a Allison Model CD-850-6A transmission. The AVDS-1790-2C (RISE) engine was a "product improved" power plant. It was rated at 750-horsepower. Special features included air-cooling, fuel injection, 12-cylinder turbocharging and modular construction. The AVDS-1790-2C diesel engine was used exclusively to power the US Army's M60 Series tanks. The Allison CD-850-6A transmission was a "full-torque" shifting transmission. It delivered power to both the right and left sprocket drive shafts while shifting gears under full-load. The CD-850-6A transmission featured fully automatic operation with driver over-control, torque converter with lockup clutch and triple differential steering.

High Performance Powerpack Configurations

High Performance Powerpack Configurations

Teledyne Continental developed high performance power-packs with the AVDS1790 Engines. The AVDS-1790-5A (908 HP) and AVDS-1790-8A (1050 HP) engines were coupled with the Renk RK-304 Transmission. The AVDS-1790-9A (1200 HP) engine was couple with either the Renk RK-304 or the Renk HSWL-284 Transmission. Some configurations also mated these engines to the ZF LSG-3000 or Allison X1100 (XT-1410) Transmissions.

Both the AVDS-1790-8A and AVDS-1790-9A engines feature fixed low-compression ratio, increased cooling, intercooled (air to air) induction air and modified fuel injection. There engines' components were interchangeable with the lower power original versions and the exteriors are similar.

The Renk Model RK-304 Tranmission was a hydro-mechanical power shift unit. It featured hydro-mechanical power shifting with integrate reversing and steering. The RK-304 used a torque converter with a lockup clutch. The torque converter was directly coupled to the engine crankshaft to eliminate the requirement for an engine flywheel. The RK-304 allowed pivot steering in neutral gear with two rotational speeds available. The RK-304 had four forward gears and two reverse gears. The lockup clutch allowed the vehicle to be push started and (with the clutch released) towed without disconnecting the final drive driveshafts.

AVDS-1790-2 Variants

AVDS-1790-2 Variants

AVDS-1790 Air Cooled Tank Engines

AVDS-1790 Air Cooled Tank Engines

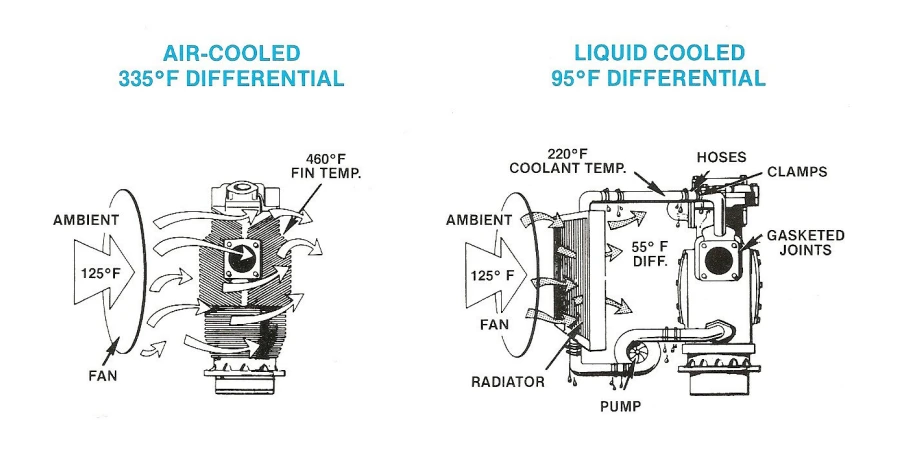

Air-cooled diesel tank engines eliminate the maintenance and service burden required by engines using liquid type cooling systems. Air-cooled engines are easier to service and repair since the hardware and plumbing required of liquid cooled units is eliminated. Air cooling provides the following power plant advantages:

- Engine bulk is reduced with the elimination of water jackets and plumbing.

- Weight reduction is achieved with the elimination of water jackets and liquid cooling hardware.

- Increased engine power-to-weight ratio is possible with the weight savings.

- Engine power loss is reduced with the elimination of water pumps and liquid circulatory systems.

- Operating temperature limitations are reduced with the elimination of antifreeze and coolant requirements.

- Logistic and maintenance problems are reduced with the elimination of liquid type coolant hardware.

In an air-cooled engine design, the cooling air is forced directly to the cooling fins of the cylinders by engine driven cooling fans. The engine heat is dissipated directly into the air and not through the water jacket as required by liquid cooling systems. This permits higher differential between the cooling air and the metal temperatures than is permissible in water-cooled engines. Therefore, higher performance output is possible from each cylinder.

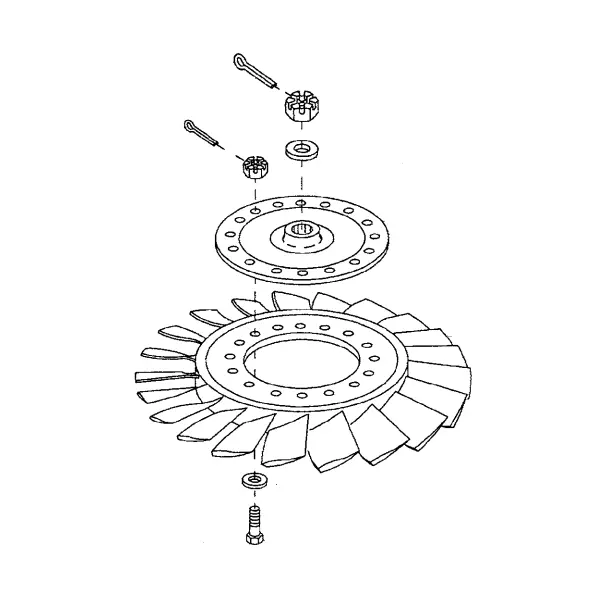

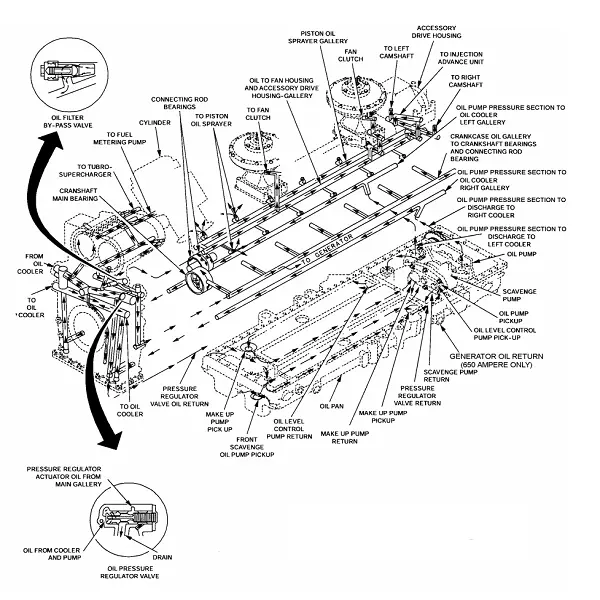

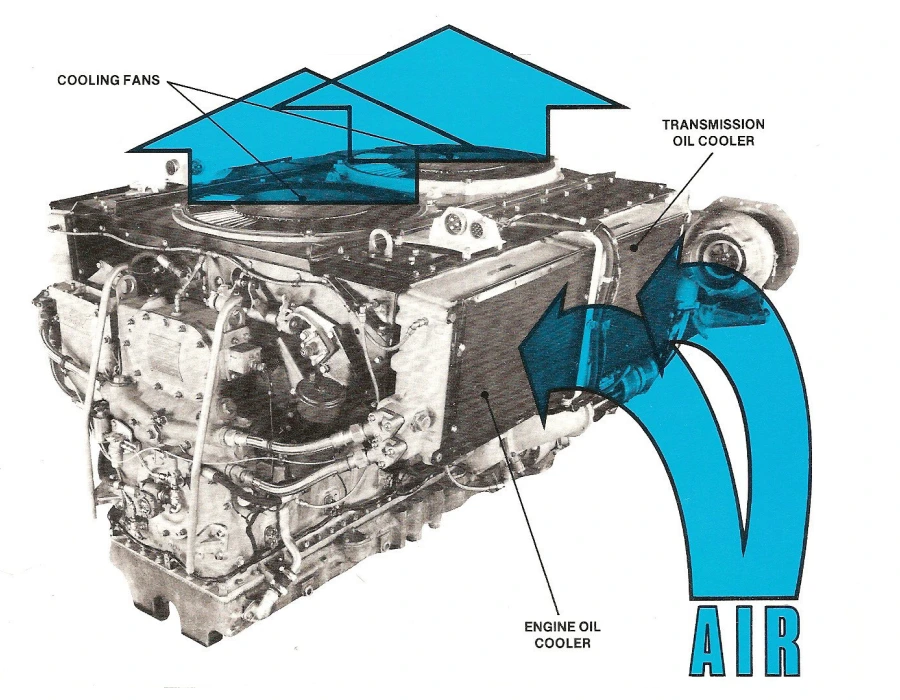

In the AVDS-1790 engine design, air cooling is provided by two engine driven fans mounted in the center of the engine Vee. These fans are used to provide total cooling for the cylinders, engine and transmission oil and also to provide ventilation of the engine compartment. The air-cooled engine design permits the transmission and engine oil coolers to be mounted on the exterior of the engine. This design reduces power pack installation area and adds additional fuel storage space. It also permits easier disconnect and removal.

Liquid cooled engines require a double-heat exchange process. In this process, heat is transferred to the coolant flowing through the engine cylinder jackets. To support this process, the installation and use of water pumps, plumbing, hoses, clamps and gasketed joints is required to carry the coolant to the radiator for dissipation into the air. The temperature limitations of antifreeze and water also restrict the differential between coolant temperature and air and therefore cooling performance. This restraint seriously limits the output of liquid cooled engines.

AVDS-1790 Modular Construction

AVDS-1790 Modular Construction

Modular construction is major design feature of all 1790 Series diesel engines. It permits the use of weight-saving aluminum components throughout the engine. These aluminum components facilitate cooling, provide high power-to-weight ratio and easy accessibility to engine parts.

The one-piece cast aluminum crankcase is ribbed and reinforced at points of greatest stress for maximum durability.

The cylinders are arranged in two banks with each containing six individually mounted Unisteel Cylinder assemblies. This arrangement provides for easy replacement and minimum teardown.

Two engine driven fans are mounted in the center Vee of the engine. They provide air cooling of the engine and lubrication system. This unique air cooling design eliminates engine bulk, water jacket requirements and the inherent problems of conventional liquid cooling systems.

Modular construction also permits easy access to engine assemblies requiring routine maintenance. The ninety-degree Vee engine design provides for easy accessibility to cooling fans, fuel injection system, turbocharger, fuel and oil filter assemblies.

AVDS-1790 Product Improvement Program

AVDS-1790 Product Improvement Program

1972, Teledyne Continental Motors Started an ambitious program for the product improvement of the AVDS-1790-2A Series engine. This program was designed to upgrade and improve the reliability of the engine.

This new product improved engine is frequently referred to as the RISE engine. It was developed as part of the US Army's Reliability Improvement of Selected Equipment (RISE) Program. All major component parts were improved with the basic engine and horsepower remaining the same.

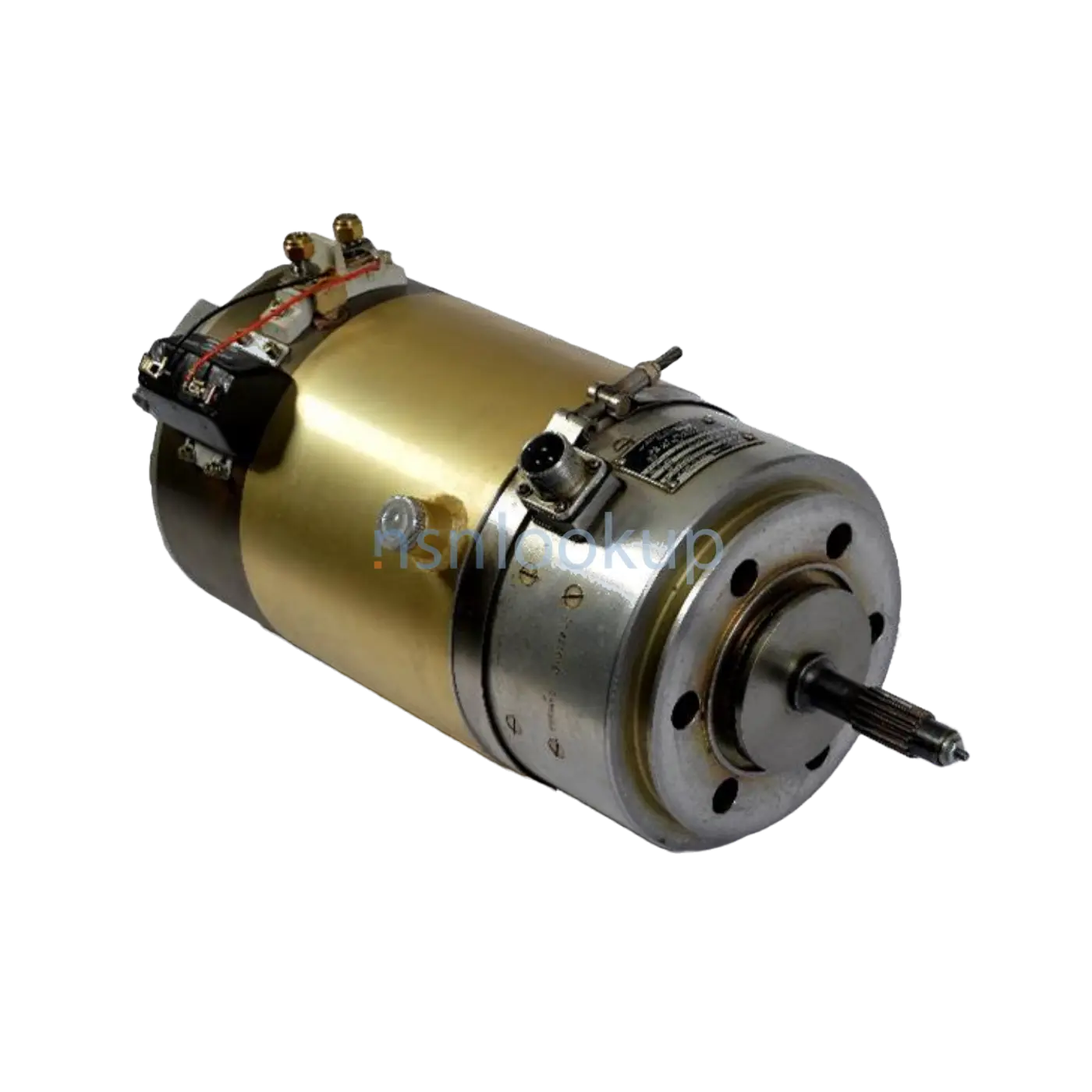

Two product improved engine models evolved from the RISE Program. The AVDS-1790-2C Series engine featured an oil cooled alternator and the AVDS-1790-2D Series engine is equipped with an air-cooled generator. Therefore, the basic product improved engine is configurated to service two different vehicle electrical systems.

In addition, the original AVDS-1790-2A engine can easily be converted to the new product improved engine by using an appropriate RISE Kit during overhaul. The US Army converted all of its operational tanks to the RISE engine configuration at depots located both in this country and overseas. The improved components of the RISE engine are:

- Generator Assembly

- Starter Low Voltage Protection

- Oil Pressure Switch and Temperature Transmitters

- Oil Cooled Alternator

- Exhaust Manifold

- Manifold Flame Heater System

- Turbosupercharger

- Engine Oil Cooler and Drive

- Oil Pan and Oil Pump

- Damper Housing and Oil Filter System

- Front Protective Guard

- Top-Side Electrical Quick Disconnects

- INTERNAL IMPROVEMENTS

- Automatic Water Drain

- Fuel Injection System

- Fuel Filter System

- Cylinders

- Pistons

- Rings

- Piston Cooling Jets

- Oil Filter Elements

- Piston Rings

AVDS-1790 RISE Unisteel Cylinders

AVDS-1790 RISE Unisteel Cylinders

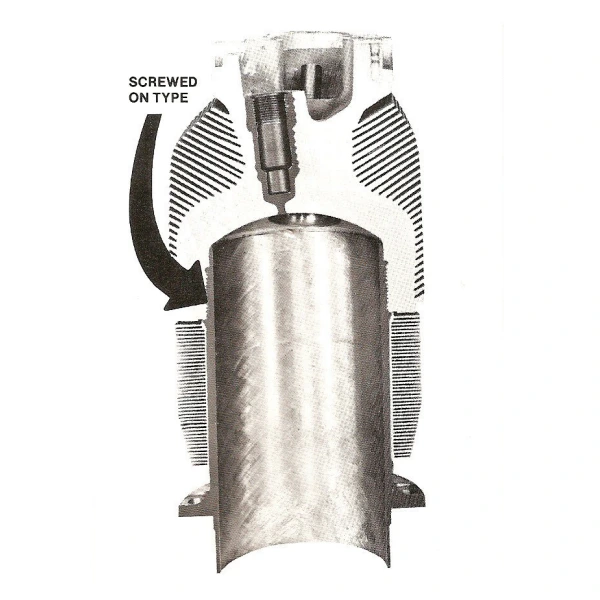

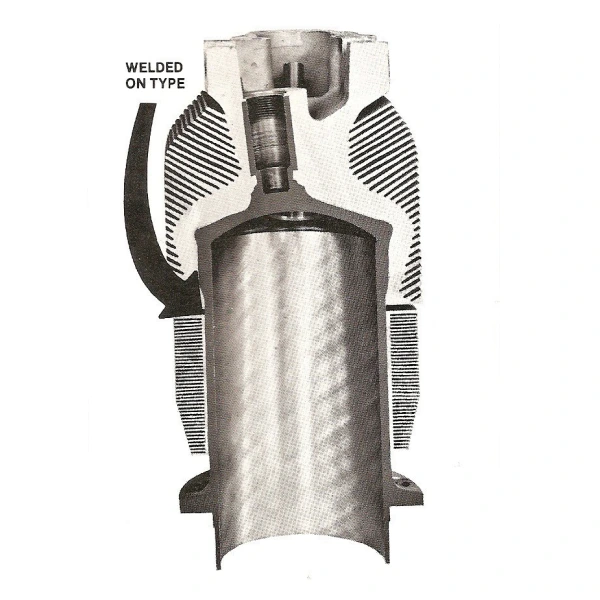

The Unisteel Cylinder was developed under the Reliability Improvement Selected Equipment (RISE) Program for the AVDS-1790-2C Series diesel engine. The original AVDS-1790 Cylinders were two-piece and screwed together with a fine-thread screw. The threaded design was robust, but in the event of an internal failure, the cylinder heads would be explosively ejected from the failing engine.

The Unisteel Cylinder is composed of an all-steel cylinder barrel and head structure with an aluminum muff and cooling fins cast to the exterior of the two parts. These two cylinder pieces are welded together by Electron-Beam Welding. The Unisteel Cylinder is designed to carry the combustion pressure and thermal loads.

Later improvements to the Unisteel Cylinder include impregnation of the cylinder internal surfaces with a "sealant" agent which minimizes seepage of fuel and lubricating oil through the limited porocity metal to the outer cooling fin surfaces. The extreme heat and pressure inside the cylinders would slowly cause fuel and oil to seep out contaminating the cooling fins and causing dust to stick to the fins causing cooling performance reduction.